Category Archives: Well Design

Benefits of 3D Geomechanics Models

Good drilling practices alone won’t save wells experiencing collapse issues, but creating accurate Geomechanics models, and continuously upgrading those models, will.

Regardless of where in the world a client’s drilling operations are, it is critical to design a drilling program that matches the rock. That’s seems pretty simple, but the truth of it is, it is not uncommon for some operators to plan their drill sites solely off of topography, and not off of downhole rock mechanics. That is not an indictment of the drilling team – in many cases, they get handed the location and are forced to begin planning wells before the geomechanics studies are even complete, and by the time they are, they are so far down the road with AFE’s and site plans and even roads, they really can’t back out and move the pad two miles in the opposite direction. They are forced to drill at whatever angle and azimuth will hit the target.

Calibrating Accurate Models

Crucial in drilling trouble-free wells

Q: What does the model say the answer is?

A: What do you want it to be?

Remember that one time you put together a wellbore model, ran it, and found that SPP, ECD, Hookload and Torque matched the actual values your rig team reported to you later on that day exactly?

Yeah, I don’t remember that ever happening either.

When designing a well, particularly when modeling Torque, Drag, Hydraulics, and Swab/Surge, we use the best inputs available. Proposed BHA’s straight from the DD coordinator, pilot-tested mud properties for the additives desired, pipe spec sheets right from the vendor themselves. We put it all together, and it doesn’t match the actual values.

It’s not supposed to – models are made to be calibrated.

Project Development Process

The Key to Deliverables

Understanding the company’s drilling project development process is key to developing a timeline and outlining the necessary deliverables. There are many different drilling project management structures that are employed by various operators that are more or less stringent depending upon the operator’s management structure and size, geologic probability of success or experience in the region. Additionally, understanding the state at which the process is currently in plays a large role. Is the drilling project fully handed over from exploration or is it in the beginning stages of defining the exploration goals to potentially move to a future development? Also, understanding if the drilling project is fast tracked, schedule driven or cost driven are extremely important when developing an execution schedule.

Identifying Drilling Project Goals

Prior to beginning the design process the goals of the development must be defined. Aside from the obvious goal of maximizing production, the full field intent of the wells and their purpose must be identified. This is highly dependent on reservoir type and quality and will dictate the design, completion option/s selected and future field operations.

Integrating Geomechanical Models With Real-Time Data

Generating Industry-Leading ERD Well Designs

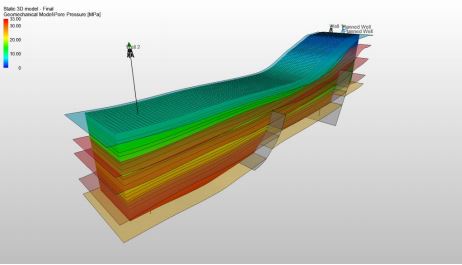

HXR provides Real-Time Geomechanical and Pore Pressure modeling using JewelSuite™ RT. JewelSuite™ RT is part of the complete JewelSuite™ 1D and 3D subsurface modeling platform. A modular software platform, JewelSuite™ is made up of PressCheck™ and WellCheck™, and is commonly used with another stress modeling program, call SFIB™. What makes these integrated software packages so powerful on the rigsite is that geomechanical models can be imported into JewelSuite™ RT, and the real-time data stream can be used to adjust the geomechanical models. This allows HXR’s Geomechanics Specialists, on the rig or in our RTOC, to quickly identify potential formation pressure and stress issues, alert the drilling team, and provide viable, accurate solutions — in real-time! Using the updated geomechanics data, engineering solutions can then be modeled by our onsite ERD Specialists, the drilling team can discuss, and parameters can easily be adjusted before a trainwreck is encountered.

A pre-drill geomechanics model, like those commonly used to design casing and mud wt windows on a given well, is only as good as its available data. The fact that the model uses offset well data will inherently generate inaccuracies and limitations to the analysis, since differences in the subsurface conditions can exist between the various offset wells and the target well itself, such as faults, fractures, changes in water depth, uplift, or truncated bedding. Streaming RT LWD data from the active well into a pre-existing geomechanical model allows the user to compare the actual values with the expected trends and identify changes in the formations expected behavior, which in turn allows the user to calibrate, or “tweak”, the pre-drill model, re-calculate it, and enhance the accuracy of its predicted values. Much like a Survey Ellipse of Uncertainty, where the more survey points you have, the more accurate your estimation of your actual wellbore position – the introduction of RT data into the geomechanics model acts in a similar fashion. The more you constrain the model and improve its accuracy while drilling in one section, it improves the prediction of pressures and stresses for sections ahead of the bit, yet to be drilled. This increase in the precision of the model looking forward can mean the difference between a trouble-free section, and quite possibly a lost section or sidetrack.

A Stable Wellbore is a Successful Wellbore

How Geomechanics is Crucial to ERD Well Design

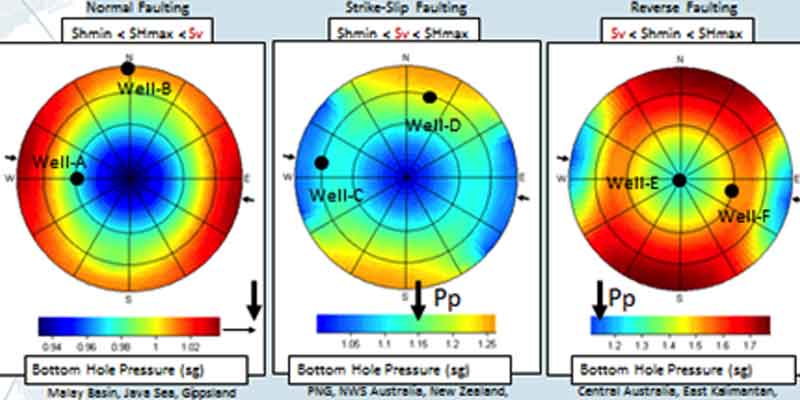

Prior to designing a drilling program for a target wellbore, it is imperative to understand the rock mechanics going on along the wellpath, as well as the target location. Subsurface interactions rely on indirect measurements, from multiple disciplines, to make interpretations about how forces, and their subsequent pressures and stresses, mechanically interact with the rock, fluids, and formations below the surface. That is critical, because if we don’t know how the rock is going to act when a certain mud type is introduced into it, or what the formation limits are in terms of mud weight or ECD, then we can’t perform a successful drillstring design or casing program.

The application of geomechanics software permits the user to investigate the location of a target well to better explain all forces and conditions the wellbore will encounter. Geomechanical studies generate a target well or a regional location’s history. This history holds information about the interactions between the various forces and materials in the earth and describes the basin characteristics that provide clues as to how the basin may have evolved and how the sediments were deposited and deformed.

(more…)