President’s Message

Can a company provide TOO MANY services?

Would you like fries with that?

That’s the punchline to an old joke from the 80’s about geologists, but recently I’ve come to the conclusion it works just as well when talking about marketing and branding issues, so unless my boss, Nicole, overrides me, that is the subject of this quarters’ ERD Magazine President’s Message. Hey, I was told I have to come up with something actually interesting this time, with some actual insight into our outfit, but this is the best I can do, okay?

(more…)

Client Specific ERD Training Courses

2 & 3-Day Horizontal, Complex/ERD & Geomechanics Training Courses … Sign Up Today!

HXR offers Client Specific 2 and 3-Day Horizontal, Complex and ERD Well Drilling and Completion Training Courses, including the integration of Geomechanics Fundamentals.

What You Will Learn:

How to effectively design, plan and implement the drilling of Directional, Horizontal, Complex and ERD wells through a multi-disciplinary approach including the latest drilling and completion technologies and techniques as well as incorporating the latest Geomechanics techniques to help avoid costly well problem surprises. (more…)

HXR’s Project Management Division is Excited to Announce our New Service Offering!

(IRIS) Integrated Re-Injection Solutions

HXR is your turnkey solution to safe and reliable true zero discharge technologies.

HXR is proud to offer the following services:

- Project Management, Engineering & Design

- Planning, Permitting & Delivery

- Field Operations Support & Monitoring

OTC & AOGA 2017 Conferences

Recaps on the Recent Oil and Gas Industry Conferences

May 1-4, 2017 Offshore Technology Conference – Houston, TX NRG Arena

May was a busy month for HXR! In the beginning of May, HXR exhibited at the 2017 Offshore Technology Conference in Houston, TX. Originally founded in 1969, OTC has become the largest event in the world for the oil and gas industry featuring more than 2,400 exhibitors and attendees representing 43 countries. In being the largest oil and gas event, it’s a place where offshore energy industry experts and leaders gather from across the world to meet and exchange ideas and opinions to advance scientific and technical knowledge for offshore resources and environmental matters. (more…)

Meet the Team

Spotlight on HXR’s Geomechanics Team

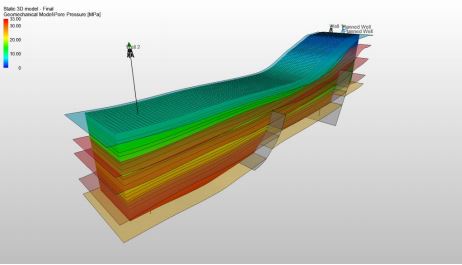

We at HXR have been staying busy during the current slowdown in drilling activity by continuing to build up our Geomechanics Team, composed of pre-drill and real-time pore pressure, fracture gradient and wellbore stability experts. We have 10 Geomechanics Consultants and 3 Senior Technical Advisors, and we partner with specialized companies, on an as-needed basis to solve unique reservoir problems for our customers. Combined, our team has nearly 200 years of industry experience in various areas around the globe, including the Gulf of Mexico, West Africa, the North Sea and the Middle East.

Benefits of 3D Geomechanics Models

Good drilling practices alone won’t save wells experiencing collapse issues, but creating accurate Geomechanics models, and continuously upgrading those models, will.

Regardless of where in the world a client’s drilling operations are, it is critical to design a drilling program that matches the rock. That’s seems pretty simple, but the truth of it is, it is not uncommon for some operators to plan their drill sites solely off of topography, and not off of downhole rock mechanics. That is not an indictment of the drilling team – in many cases, they get handed the location and are forced to begin planning wells before the geomechanics studies are even complete, and by the time they are, they are so far down the road with AFE’s and site plans and even roads, they really can’t back out and move the pad two miles in the opposite direction. They are forced to drill at whatever angle and azimuth will hit the target.

The Importance of Optimization

In a Downturn Market….

In today’s market of ultra-low oil prices, if you are still drilling, optimization of your drilling program should be/could be your missing link. We are now in a time of uncertainty that is setting records, and they aren’t good records. Rig counts are at all-time lows. If you are one of the few brave companies gutting it out during the slump and still drilling ahead, you are faced with some difficult decisions. Where do I cut cost? What cost can I cut without sacrificing performance? Do we even continue the drilling program? One option that few companies even ponder is spending money! How can you safely spend money and take on a new addition to overhead in such a market? Honestly, it’s quite simple. You should be focused and or have someone solely focused on drilling optimization from head to toe.

Here We Go Again, Folks!

Since the last issue of ERD Magazine, our friends at OPEC have started making some very subtle noises that they may be just about done trying to bankrupt themselves (and everyone else in the process…), and IF that is the case, it may be time for our clients to dust off all of those projects that have been on a shelf since the end of 2014, and take another look at them. I can’t speak for everyone in the Horizontal/ERD, wellbore stability/geomechanics or deepwater drilling fraternities, but I can say that many of us aren’t expecting too much for the remainder of the year; maybe Q4(?). If we do get back to drilling, who’s going to actually do it? We’ve laid off half of Houston, it seems, and I’m hearing Aberdeen isn’t much better off… I know I’ve had to lay off, folks – nothing for it, to be honest. Luckily, they were top-notch ERD hands, and were able to, unbelievably, find something IN THE INDUSTRY, when many others were cleaning out their desks and lockers. Can I get them back? I sure hope so; those are going to be some tough phone calls… Maybe we’re about to get back at it.

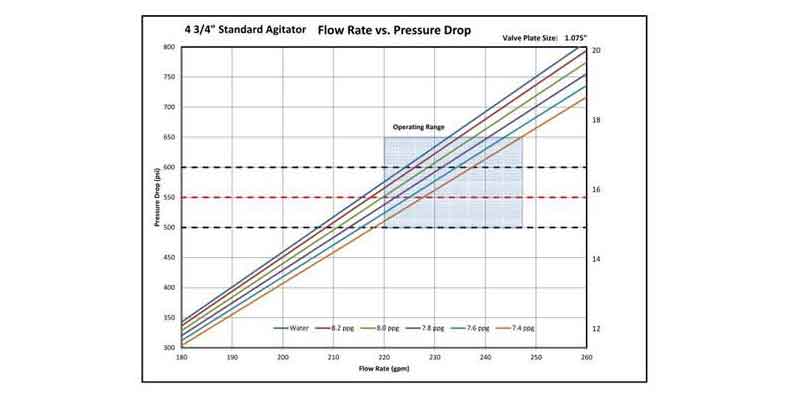

Are You Getting the Most Out of Your Agitator?

What are the Key Components to a Successful Agitator Run?

In a time of low oil prices, it doesn’t always make economic sense to some operators to run a rotary steerable system, as beneficial as they can be in terms of smoother wellbores and higher sustained ROP. Many clients turn to straightforward “motor and mwd” systems, and find they are cost effective, reliable, and provide sufficient quality wellbores for their casing programs. The issue becomes what are the limits, in terms of trajectory complexity and step-out, that an agitator can be used, and how do you judge the effectiveness of the tool?

HXR’s Drilling Specialists use a graphical method to measure agitator efficiency and placement. What some may not know is that there is a fairly small input window in which your agitator is working at peak performance. The window of opportunity for optimization gets smaller each time one of the key components change. Here are the key components to a successful agitator run: