Providing Solutions to Pore Pressure and Wellbore Stability Issues Encountered While Drilling

HXR Drilling Services Geomechanics Division can provide solutions to pore pressure and wellbore stability analysis uncertainties for stable wellbore trajectories and determination of optimal mud weights.

A calibrated regional area, using analogue wells, can provide sufficient data to study subsurface pore pressures and to analyze characteristics contributing to wellbore instability. After collecting data, a pore pressure 1-D model and a wellbore stability (WBS) model can be generated based on client goals and data availability.

Pore pressure (PP) predictions include pore pressure values to indicate mud weights needed downhole and identify fracture gradients (minimum horizontal stress). Typically Eaton’s equation, derived from Mathews and Kelly equation, is the most widely used procedure for both on and off shore fracture gradient calculations. The equations are similar with Eaton adding Poisson’s ratio, however the values produced are similar enough to use either equation. Equations are typically given using 3 different matrix stress coefficients (Ki) 0.6, 0.7, and 0.8, which are empirically determined values displaying different geological conditions. The equation makes the assumption sediment bulk densities are similar at deep and shallow depths. The fracture gradient won’t include stress concentration effects around a wellbore or any tensile strength of intact rock. It will assume that a wellbore is likely to have intersected a pre-existing fracture oriented in the most critical direction. After calculating PP and the minimum horizontal stress, a geomechanical model specifically designed to analyze for WBS problems is generated. Based on this information, casing placement and other downhole needs can be developed.

HXR Drilling Services Geomechanics division offers a method to evaluate regional data and analogue wells to generate a model that can be used for pore pressure (PP) prediction and wellbore stability analysis along a wellbore path. These models alleviate the “trial and error” by providing PP’s to plan for mudweights and type and the most likely weak spots prone to fracture along the pathway of the wellbore. A PP model and WBS model limits the parameters and narrows down the number of potential scenarios downhole, within the restraints of the regional calibration.

Prior to a wellbore stability analysis (WBS), a pore pressure 1-D model is built. The 1D PP model calibrates and generates the regional subsurface conditions. The process begins by collecting available information on wells drilled in the same geologic basin, such as well logs, daily drilling reports, leak-off tests, and other available data. The overburden, pore pressure and fracture gradients are calculated and analyzed. The 1-D analysis calibrates analogue well information and provides excellent vertical resolution while seismic data fills in horizontal gaps.

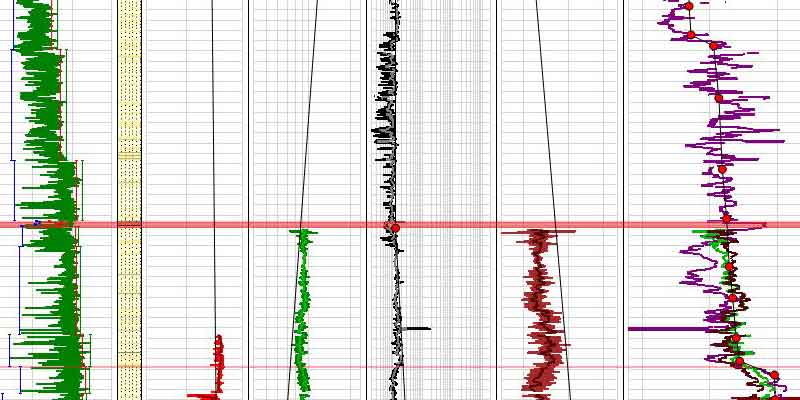

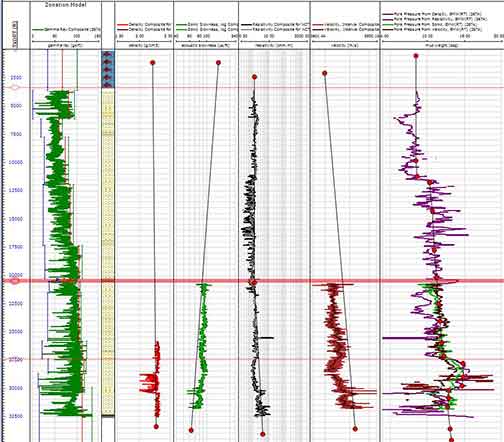

1D-Model of an Analogue Wellbore

Example of a 1-dimensional model displaying an analogue wellbore and data including: Shale Points from Gamma Ray, Lithology, Overburden Calculation (OBG), Fracture Gradient (FG), Pore Pressure from Resistivity

The pore pressure 1-D model provides calibration and also is used to recognize the pressures acting against the principle stresses. After the 1-D calibration model is completed and conditions causing the predicted pore pressures modeled, then a wellbore stability analysis & geomechanical model can be built to help determining breakout and fracture positions. Wellbore breakouts and tensile wall fractures can be obtained through this model by forward modeling. The model also reveals tendencies for compressive and tensile wellbore failure.

Using the 1-D pore pressure information is critical because it acts against the principle stresses X, Y, and Z, described by Terzaghi’s Principle. A WBS model is a very detailed model of wellbore stress conditions based on a stress (load) and the strength (load resistance from PP) model.

Wellbore Stability Analysis Preparation

Interpreted PP, OBG Stress, Horizontal Stress Minimum and Maximum, Fracture Gradient, UCS Unconfined Compressive Strength, Internal Friction Coefficient, Static Poisson’s Ratio, Inclination, Azimuth, Wellbore Azimuth SHMaximum, Breakout Width

The value of the maximum horizontal stress is key to a wellbore stability analysis. This cannot be measured directly so other methods to infer the measurement are necessary.

The software used by HXR Drilling Geomechanics team, generates a model to calculate stress distribution. The stress distribution includes the 3 principle stresses that exist around a wellbore. The target well information, such as location, inclination, and azimuth, is critical at this point.

The software is capable of generating modules that constrain the complete stress tensor using observations of failure in indiscriminately oriented wellbores. It also predicts wellbore failure and acts as a great tool to determine optimal drilling trajectories and mud weights. Knowing the goal of the client helps to define the best suited model(s) for the available data which determines the stresses to predict failure conditions.

For example, the chemoporoelasticity model, analyzes the effect of mud chemistry on wellbore stability. The data displayed in an output plot showing the failing fraction of the wellbore’s circumference due to mud/pore fluid interaction. The contour plot of the failing fraction of the wellbore‘s circumference (twice the breakout width) is a function of the chemical activity of the drilling fluid and the membrane efficiency of the wellbore wall, due to mud/pore fluid interaction, for the given stress and rock properties.

Within the wellbore stability analysis model, rock strength and other rock properties are used to define the model conditions. Rock strength is scale dependent and varies with the volume of rock. An unconfined compressive strength and frictional properties describes rock strength and failure criteria for intact rocks and rock masses.

Higher pore pressures, due to a rise in formation temperature can cause chemical solutions that can affect the compaction of the layers. HXR Drilling Services Geomechanics can located the areas and also look at the temperature from analogue wells for the analysis. These types of situations can cause movement of the bedding towards lower pressure areas.

The geomechanical model will be used for pore pressure prediction and wellbore stability analysis by developing constraints. This essentially shrinks the number of possibilities of potential conditions downhole. A geomechanical model also indicates where conditions favor wellbore instability so modifications of the target wellbore can be anticipated. The model defines pressure limits and predicts where events relating drilling fluid loss, formation fluid influx and wellbore stability analysis problems most likely exist. A casing and fluids program can then be contrived to avoid conditions that would cause a failure.

Several case scenarios can be generated to provide a solid understanding of what conditions are possible down hole based on location and trajectory. A benefit to developing a geomechanical model prior to drilling, in addition to calculating a PP and WBS, is the trajectory or the targeted location can be shifted or location moved.

Providing data for analogue wellbores is essential for defining the area and exposing faults, lithology, and other geologic features. Seismic cross sections are useful in identifying large scale features such as salts and faults. After necessary data is gathered then a series of calculations can generate OBG, PP, and minimum stress gradient. Industry standard for pore pressure prediction ranges is to stay within 0.5 ppg deviation.

In summary, a pore pressure 1-D model and a WBS model is very useful in planning casing depths, mud type and weight. A well calibrated area, generates subsurface pore pressure and fracture gradients and then is imported by a software specially design to analyze characteristics to check WBS. The results of any model are dependent on the quality and quantity of data received related to the region.

About the Author

Posted on: November 3rd, 2015

Filed under: Blog, Engineering Software, Geomechanics, Pore Pressure, Pore Pressure Evaluation, Software Solutions, Wellbore Stability